Hi - and thanks in advance for reading - just joined...

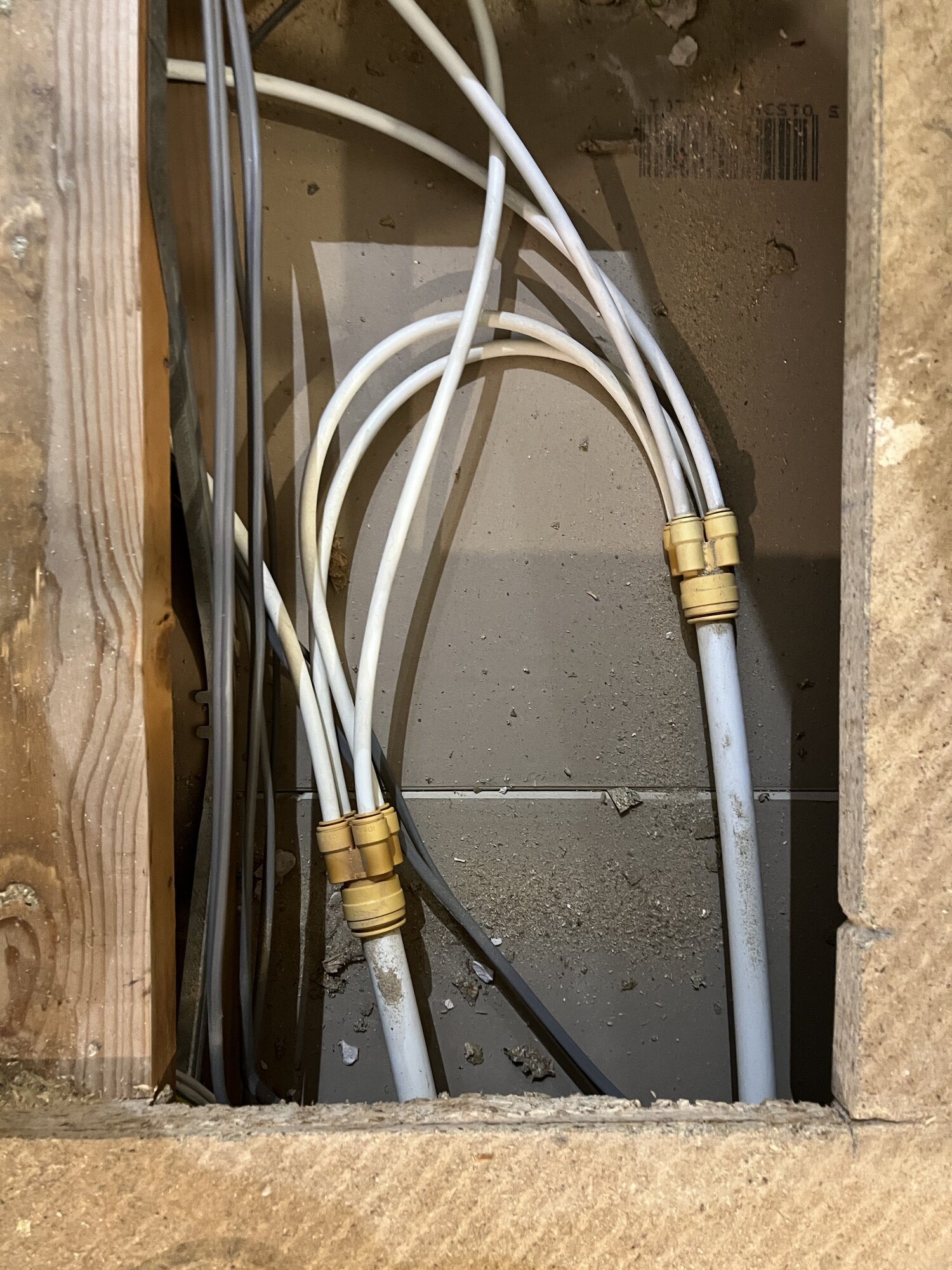

I have been looking into why my heating takes ages to warm up - had the system power flushed and lots of things checked... Today, I found this:

This is one of 4 manifold pairs - and it also feeds the worst of the radiators for not warming up.. Is it correct or normal to have the two loops from flow to return like this?

The bypass loops are (predictably) lovely and (ouch) hot - the feed to the rad gets hot-ish after a while and the return from the rad barely warms up at all, this is with the stop valve on the rad open and the TRV removed. The radiator has ben taken off and flushed out with a hose as well.

Is this in any way normal practice? Can I fit 4 blanking plugs and rely on the bypass pressure relief valve? - It is marked from 0.1 to 0.5 bar, any good starting point for settings would be appreciated!

FYI, 15 rads in all on Viessmann 100-W 19KW boiler, house built 2002

Thanks for reading - any ideas and info much appreciated

I have been looking into why my heating takes ages to warm up - had the system power flushed and lots of things checked... Today, I found this:

This is one of 4 manifold pairs - and it also feeds the worst of the radiators for not warming up.. Is it correct or normal to have the two loops from flow to return like this?

The bypass loops are (predictably) lovely and (ouch) hot - the feed to the rad gets hot-ish after a while and the return from the rad barely warms up at all, this is with the stop valve on the rad open and the TRV removed. The radiator has ben taken off and flushed out with a hose as well.

Is this in any way normal practice? Can I fit 4 blanking plugs and rely on the bypass pressure relief valve? - It is marked from 0.1 to 0.5 bar, any good starting point for settings would be appreciated!

FYI, 15 rads in all on Viessmann 100-W 19KW boiler, house built 2002

Thanks for reading - any ideas and info much appreciated

Last edited: