Just wondering what kind of hysteresis blending valves operate to, presume not as tight control as say shower thermostatic valves etc. This will have a big effect on how much water is recirculated by the UFH TMV, presumably none as the TMV is coming up to temperature from cold so all the UFH water is supplied and then boosted by the manifold pump until almost up to the required UFH temperature, has anyone watched this temperature from cold and noticed any over or under shooting or any changes in the manifold flow rates?.

-

NavigationPlumbing Advice Forums UK Plumbers Forums USA Plumbing Advice Australia Plumbers Talk Canada Plumbing Zone Forum Ireland Plumbing Advice

Bathrooms, Showers And Wetrooms DIY Plumbing Advice Plumbing Courses Water Underfloor Heating Advice Plumbing Tools Renewables Plumbing Zone Commercial and Industrial Plumbing Forum Specialist Plumbing Forum Oil And Solid Fuel Forum G3 Unvented Forum

Gas Engineers Advice Central Heating Forum Gas Engineers Forum

PF Community Forums Welcome Forum Plumbing News General Chat

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Discuss Not enough hot water if UF heating is running at same time time as HW in the Central Heating Forum area at PlumbersForums.net

G

Graham W

Thanks to everybody for the input. Some of the comments may be a bit above my pay grade but I get the general drift.

Not sure what is meant y the boiler flow temperature but the dial for the heating on the boiler is at 68 C?

Running the DHW for an hour before the UFH came on this morning has made a big difference. Shower water was much hotter and there is still hot left over afterwards.

The UFH has been set to run from 0700 to 2100 up to now, but I'm happy to switch it to 24 hours because I get the point about the inefficiency of the slab cycling up and down.

But will that make much difference to my situation where because of the high insulation and solar gain during the daylight there is no need for the UFH during the day and almost no call for it in the evening unless it is particularly cold?

We have a flueless gas fire in the living area which we use to add a bit of extra heat if needed in the evening / to get the visual benefit of the flames.

Not sure what is meant y the boiler flow temperature but the dial for the heating on the boiler is at 68 C?

Running the DHW for an hour before the UFH came on this morning has made a big difference. Shower water was much hotter and there is still hot left over afterwards.

The UFH has been set to run from 0700 to 2100 up to now, but I'm happy to switch it to 24 hours because I get the point about the inefficiency of the slab cycling up and down.

But will that make much difference to my situation where because of the high insulation and solar gain during the daylight there is no need for the UFH during the day and almost no call for it in the evening unless it is particularly cold?

We have a flueless gas fire in the living area which we use to add a bit of extra heat if needed in the evening / to get the visual benefit of the flames.

- Messages

- 1,271

Providing your room is warm enough anyway, the stat won’t kick in unless there’s a demand. Even if you set it to 24/7.Thanks to everybody for the input. Some of the comments may be a bit above my pay grade but I get the general drift.

Not sure what is meant y the boiler flow temperature but the dial for the heating on the boiler is at 68 C?

Running the DHW for an hour before the UFH came on this morning has made a big difference. Shower water was much hotter and there is still hot left over afterwards.

The UFH has been set to run from 0700 to 2100 up to now, but I'm happy to switch it to 24 hours because I get the point about the inefficiency of the slab cycling up and down.

But will that make much difference to my situation where because of the high insulation and solar gain during the daylight there is no need for the UFH during the day and almost no call for it in the evening unless it is particularly cold?

We have a flueless gas fire in the living area which we use to add a bit of extra heat if needed in the evening / to get the visual benefit of the flames.

- Messages

- 2,558

The accuracy of manual and electronic mixing valves is pretty good. There may be a slight hysteresis but I can’t imagine much at all. Remember UFH manifolds should have a thermal cut off switch whereby if the flow temperature to the manifold is excessive (due to a failed valve etc) then power is cut to the pump and no flow is permitted through the loops. This is to protect any screeds, slabs etc and any bare foot homeowners.Just wondering what kind of hysteresis blending valves operate to, presume not as tight control as say shower thermostatic valves etc. This will have a big effect on how much water is recirculated by the UFH TMV, presumably none as the TMV is coming up to temperature from cold so all the UFH water is supplied and then boosted by the manifold pump until almost up to the required UFH temperature, has anyone watched this temperature from cold and noticed any over or under shooting or any changes in the manifold flow rates?.

Let’s take a working example. Say we have an exact 20kw heat loss at design max load. Say 10kw for UFH and 10kw for space heating. Quite large loads but I’m using it as an example.

Using mad flow rate you will see a 20kw boiler aiming for a ΔT of 20°c will have a flow rate of roughly 14.285 Lpm. Now the UFH which requires roughly three times the flow of a boiler or emitter targeting a ΔT of 20°c has a flow rate of 20.408 Lpm at a ΔT of 7°c across the loops. From those figures you should already see a potential problem arising.

Now let’s say the UFH was off overnight and the slab cooled to 10°c. When the UFH first comes on in the morning the return water to the boiler will be at, or very near to 10°c. Any pipe work above ground might have some negligible temperature difference. If you know the volume of the boiler heat exchanger and the flow rate through the boiler you can calculate how long water entering the boiler takes to leave with a temperature increase of 20°c. Say a 5 litre exchanger and a flow rate of 14.285 Lpm converted to alps = 0.238 Lps. 5/0.238 = 21.008 seconds for water entering the boiler to leave at 20°c higher.

So after 21 seconds we have a new flow temperature of roughly 30°c. Again if you know the volume of pipe work and flow rates you can calculate how long that water takes to reach the manifold. So the water arrives at the blending valve at 30°c but the target temperature leaving the valve will be around 45°c. From here you can see all the flow from the boiler will be pulled by the UFH pump. Now as the slab temperature increases over time so shall the return temperature and in time the boiler flow temperature will rise and the blending valve will need less and less water from the boiler flow. Say the boiler flow is at 65°c and the UFH return 37°c after some time. Using mass flow you can calculate that the UFH will pull around 5.1 Lpm from the boiler, leaving roughly 9.18 Lpm spare if you will. This 9.18 Lpm will be circulating around the space heating, or cylinder, or both, which if designed properly is enough to make the system function.

From the above you should clearly be able to see that if you let a slab go cold overtime then when you do bring the UFH on again it will initially steal all the flow until the slab and return temperature start to rise.

This is exactly why myself and EvilDrPorkChop have stated that UFH should be on constantly. They are designed to be left running to provide a nice even room temperature throughout the day, not switch on and off when you feel like it.

Agree that UFH works best on 24/7, it's not clear (to me) if Graham W's CH consists of UFH only, if so then even from a cold 10C start one might expect the boiler, firing at 100%, to only take minutes to reach a required UFH manifold temp of 45C, the TMV should then start throttling the boiler flow more and more as the boiler carries on to its setpoint temp of 70C or whatever. Calling for DHW at the same time will obviously slow down the process but one might still expect the cylinder to be fully heated to 60C in 2 hours, especially with a 37KW (not range rated) boiler. If there is a temperature gauge installed in the manifold it would be very interesting to see how long this takes to reach 45C from a cold start with both systems calling.

- Messages

- 2,558

If a slab is allowed to cool to say 10°c that’s an awful lot of mass that needs to be heated again before the return temperature starts to rise.

From a cold start a temperature gauge and timer would give a good indication to the time it takes for water to reach 45°c but remember even when the boiler flow is at 45°c the manifold will still be pulling all the boiler flow. Only when the boiler flow increases above UFH target flow temperature will the mixer start to throttle in. Use the heat balance equation and you will see.

From a cold start a temperature gauge and timer would give a good indication to the time it takes for water to reach 45°c but remember even when the boiler flow is at 45°c the manifold will still be pulling all the boiler flow. Only when the boiler flow increases above UFH target flow temperature will the mixer start to throttle in. Use the heat balance equation and you will see.

It requires 15.7kwh to heat 300 litres of water from 15C to 60C, in two hours the boiler (if not range rated) would/could have produced 74kwh, so if the cylinder had reached 60C then the manifold loops would have emitted 58.3kwh or a heat output of > 29kw, the cylinder, apparently wasn't reaching this 60C so the loops output even greater or the cylinder coil is very modest or the boiler is range rated IMO, but we'll never know but the OP is happy now so doesn't really matter.

- Messages

- 2,558

I don’t know the boiler output or UFH output but the problem with UFH is the amount of flow it requires due to smaller ΔT. If the slab or screed is cold or you start introducing some form of modulating controls etc then the UFH will pull more and more from the boiler. In a situation like this keeping the UFH constantly will solve the problem and ideally have the design flow temperature for the rads at 20°c higher than UFH return will keep the system flow nice and balanced.

If the UFH demand was irregular then realistically you would consider some sort of separation with a common flow sensor signaling the boiler to increase the flow temperature if needed.

Separation is not something I’m really familiar with though. I understand it and the problems it can cause if used when not needed but there are for more qualified people to discuss that out there than myself.

If the UFH demand was irregular then realistically you would consider some sort of separation with a common flow sensor signaling the boiler to increase the flow temperature if needed.

Separation is not something I’m really familiar with though. I understand it and the problems it can cause if used when not needed but there are for more qualified people to discuss that out there than myself.

exedon2

Esteemed

- Messages

- 978

John over shooting temperatures when system not operated properly is very common.Just wondering what kind of hysteresis blending valves operate to, presume not as tight control as say shower thermostatic valves etc. This will have a big effect on how much water is recirculated by the UFH TMV, presumably none as the TMV is coming up to temperature from cold so all the UFH water is supplied and then boosted by the manifold pump until almost up to the required UFH temperature, has anyone watched this temperature from cold and noticed any over or under shooting or any changes in the manifold flow rates?.

We're polypipe registered underfloor contractors,regularly called to look at systems we haven't installed.

Most common complaint is temperature over shooting virtually alway caused by customer miss use/ poor set up by installer.

Run it 24/7 with max of 4 c back set and it will heat rooms perfectly (assuming enough heat output)

A lot of real problem ones are either diy or installed by screed team.

Pipe distances too great screed too thin pipework not pressurised or even tested before screed going down seen it all.

- Messages

- 2,558

It’s also worth noting that the controls strategy for any hydronic heating system is important to get right at the design stage. If a dwelling has high occupancy and/or high internal gains like solar gain etc then you should consider a closed loop system with some sort of room influence. I’m an oil burner technician by trade so I’m not overly familiar with heating systems like an installer should be but I’m lucky enough to have been taken under the wing of some very knowledgeable people who do this day in day out. I have heard a lot of temperature overshoots in situations like UFH in conservatories with high solar gain and simple on/off room stats. In a situation like that you would require some sort of room influence which like an on/off stat is constantly aware of the internal temperature but also learns and calculates and adjust the boiler flow temperature to prevent any undesirable overshoots.

Although on/off controls work and have done for decades they really are primitive compared to modulating controls.

Although on/off controls work and have done for decades they really are primitive compared to modulating controls.

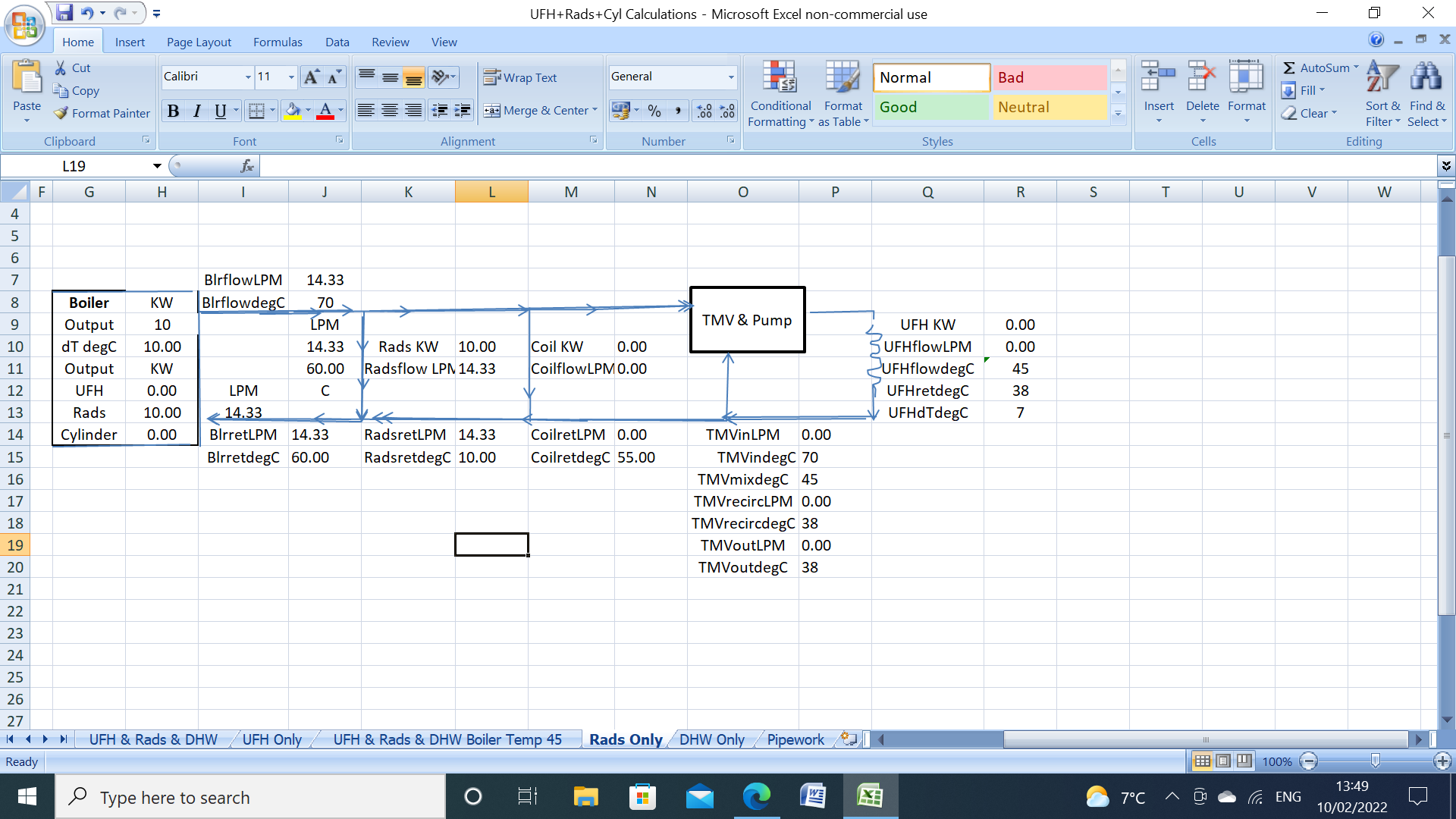

Edit: Rads returns should be 60C, with 70C boiler temp, (I copied wrong cell) but calcs are basically quite correct.

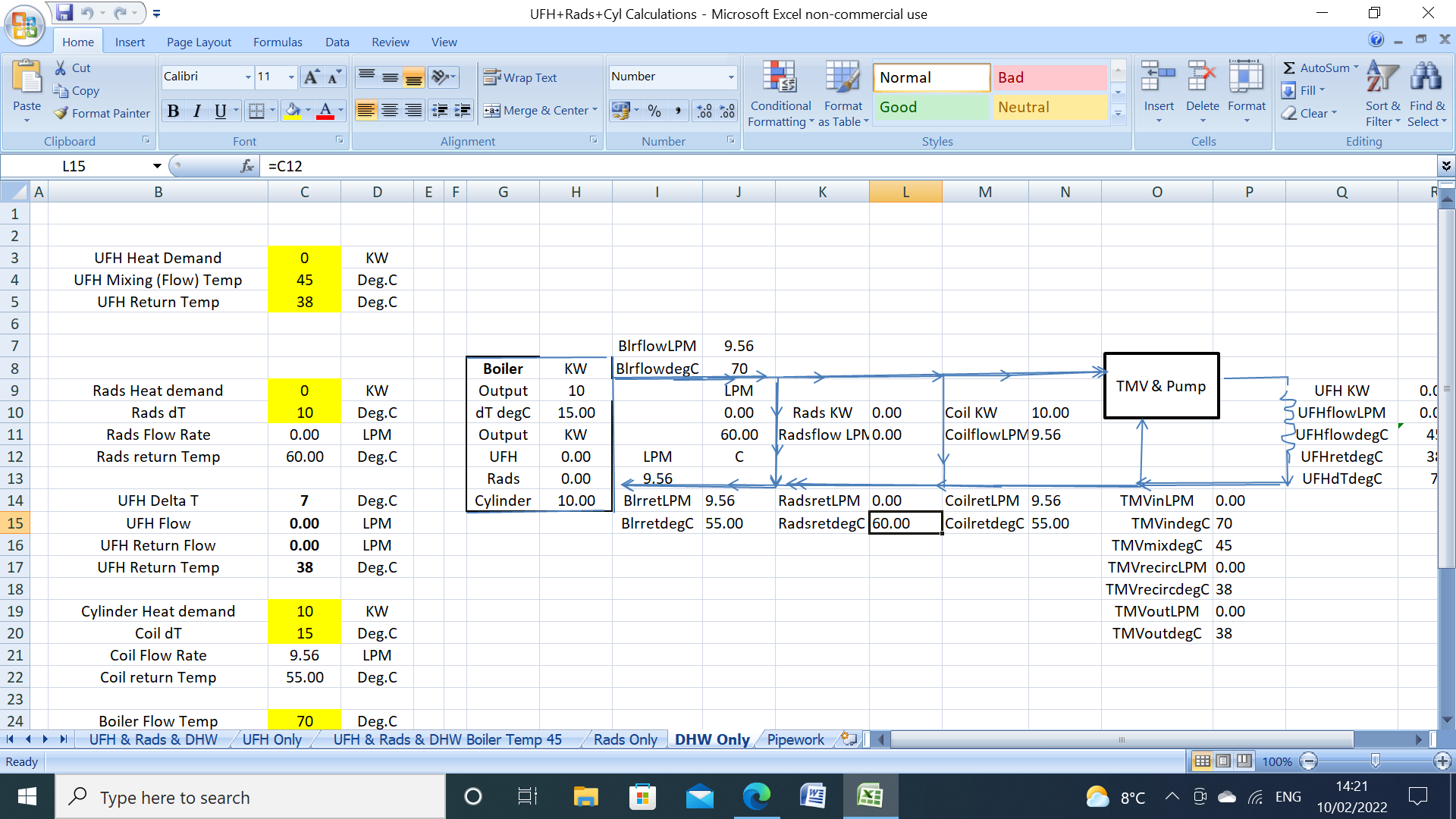

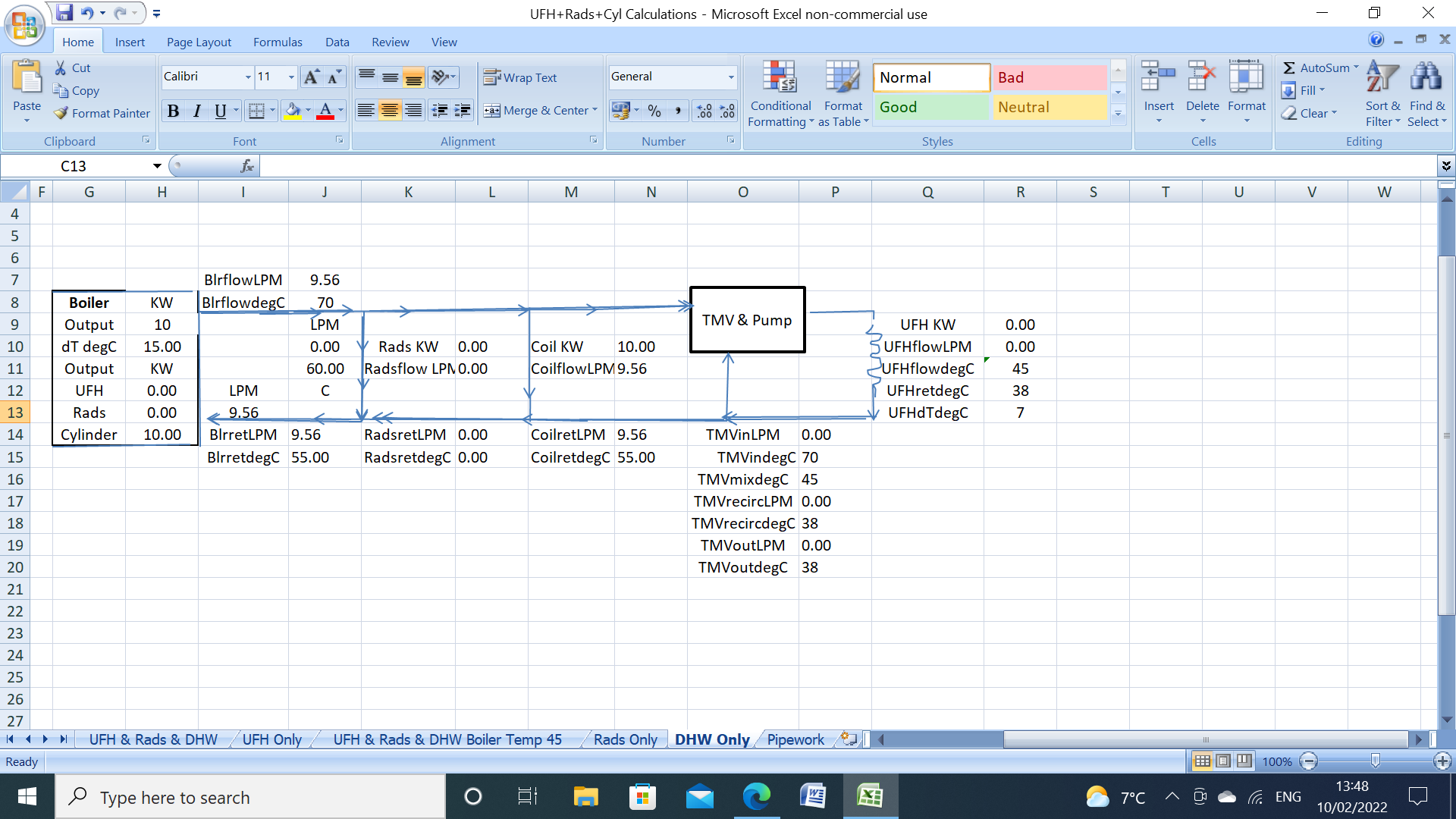

DHW sheet attached

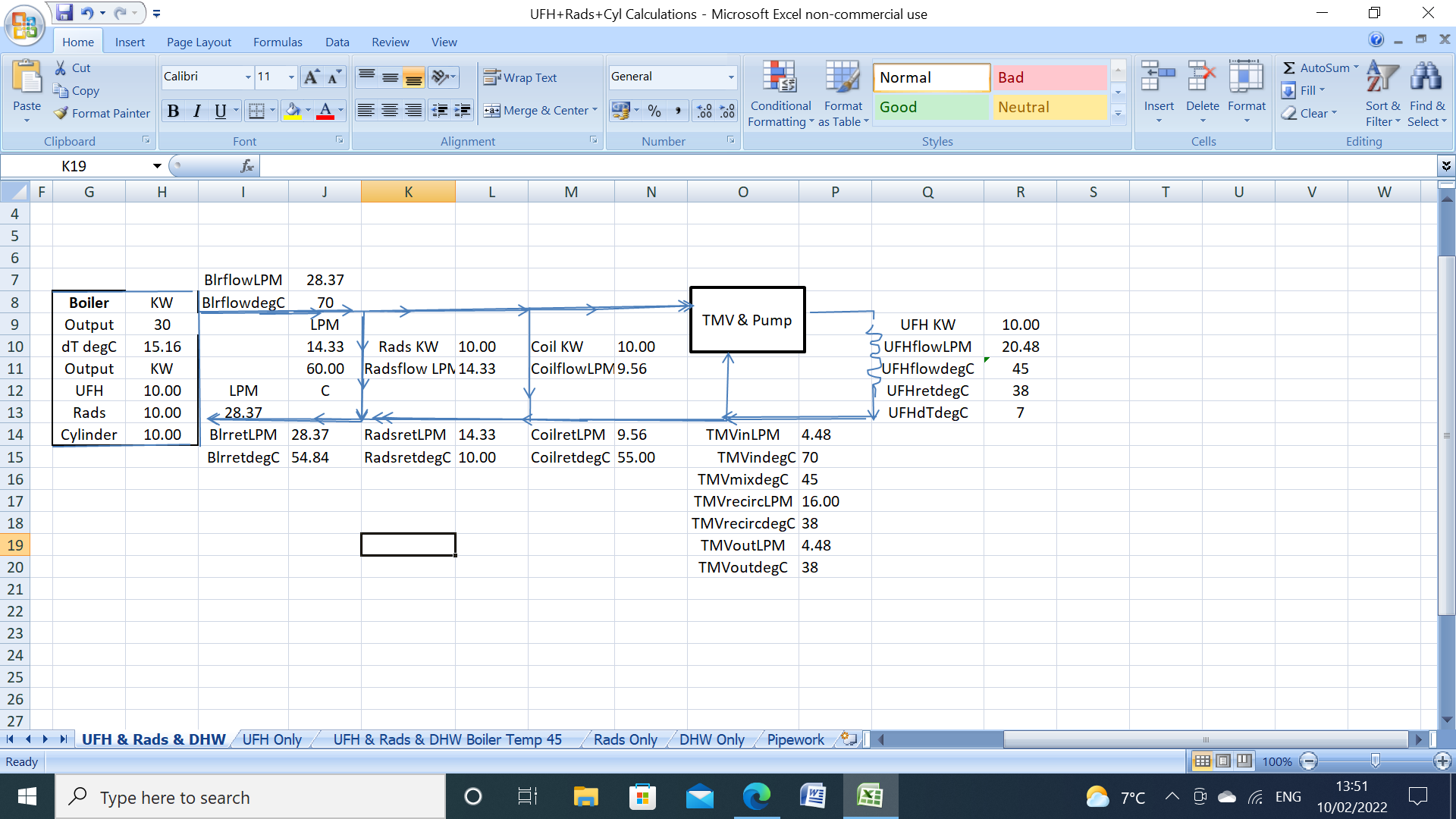

Actually I see that there are rads in the above system so I just inputted a few numbers in my spreadsheet which may (or may not) be interesting.

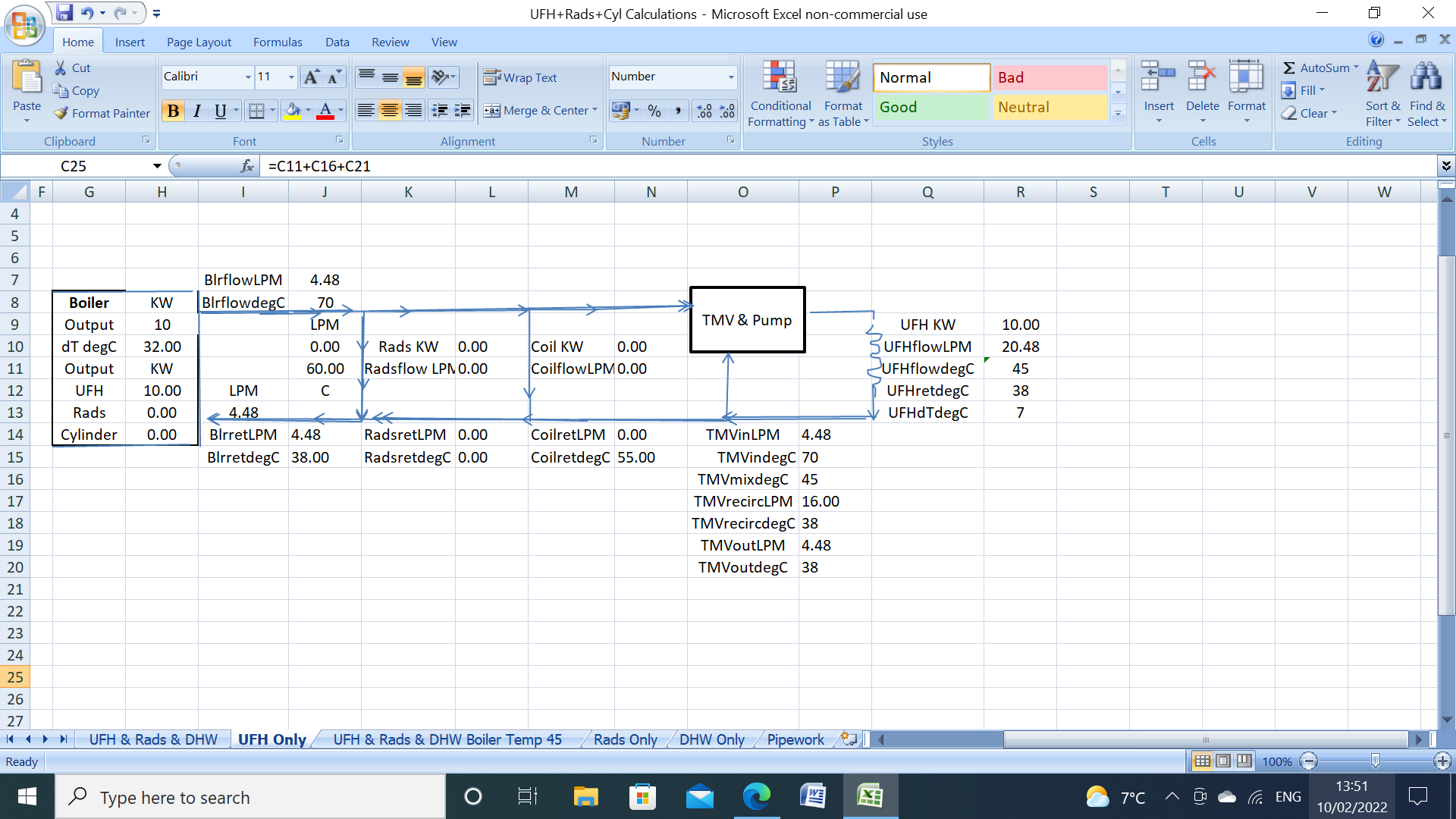

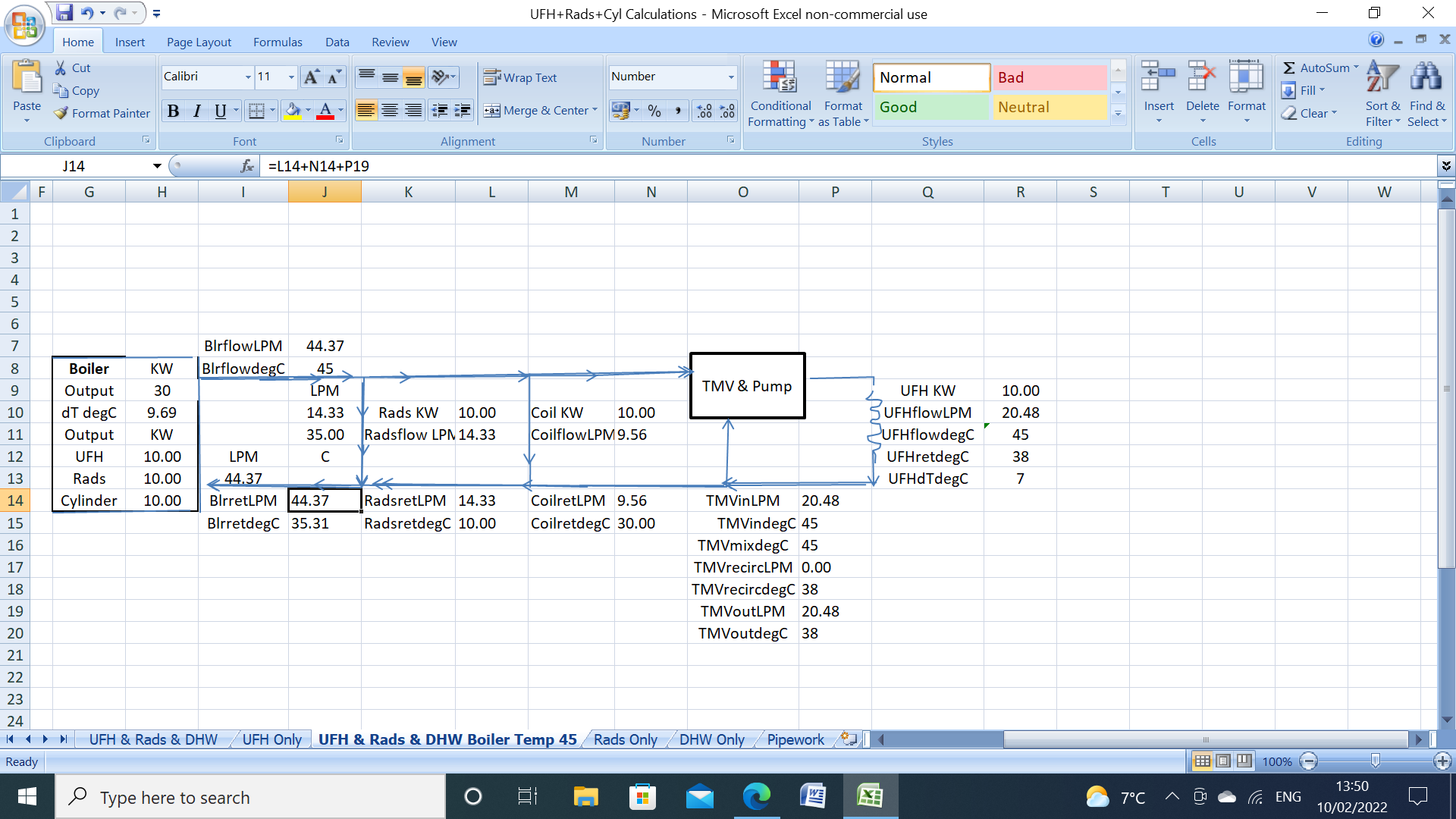

Assuming UFH demand only of 10kw only requires a boiler circ pump flowrate of 4.48LPM@70C, this means the boiler will run with a dT of 32C, maybe problematic for some makes?. the only other remarkable is if the boiler temp is either reduced to 45C or the point that you are all making, that it has fired up from cold and hasn't become > 45C so the boiler pump circ rate would have to be 44.4LPM v/vs 28.4LPM with boiler temp at 70C (all 3 systems calling), hence the slow cyl warm up time or whatever?.

DHW sheet attached

Actually I see that there are rads in the above system so I just inputted a few numbers in my spreadsheet which may (or may not) be interesting.

Assuming UFH demand only of 10kw only requires a boiler circ pump flowrate of 4.48LPM@70C, this means the boiler will run with a dT of 32C, maybe problematic for some makes?. the only other remarkable is if the boiler temp is either reduced to 45C or the point that you are all making, that it has fired up from cold and hasn't become > 45C so the boiler pump circ rate would have to be 44.4LPM v/vs 28.4LPM with boiler temp at 70C (all 3 systems calling), hence the slow cyl warm up time or whatever?.

Last edited:

Reply to Not enough hot water if UF heating is running at same time time as HW in the Central Heating Forum area at PlumbersForums.net

Similar plumbing topics

- Replies

- 12

- Views

- 826

- Replies

- 2

- Views

- 365

D

- Replies

- 0

- Views

- 301

D

Newest Plumbing Threads

-

-

-

-

Disconnecting a bath! How to cap off the tap supplies?

- Started by leogames

- Replies: 3

-

looking for some ACS mock/past paper, can anyone help?

- Started by tsxho0526

- Replies: 1

-

JDrainage camera faults and where to fix?

- Started by Jenevora Murray-Forman

- Replies: 0

-