Heating issues. Had new water pump fitted 3 weeks ago, new 3 port valve 18 months ago, boiler is 4 years old. I balanced radiators when new pump was installed and for 2 weeks or so the heating and hot water worked a treat. 3 days ago, woke up to find neither working properly. Timer comes on, boiler fires up but radiators downstairs not getting warm. Hot water not great. Balanced radiators again and all was fine but last two days every time I turn heating on nothing warm downstairs in spite of balanced radiators two days ago working fine. Pump does seem to work fine when it runs quietly but each time it starts there is a whirring noise and you know it won't work properly. Any ideas?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Discuss Any ideas? Unreliable heating. in the Central Heating Forum area at PlumbersForums.net

- Messages

- 34,337

- Solutions

- 2

What’s the make of the pump ?

GrundfosWhat’s the make of the pump ?

- Messages

- 34,337

- Solutions

- 2

Grundfos

Black one or red one ?

BlackBlack one or red one ?

- Messages

- 34,337

- Solutions

- 2

Ups3 any red lights when running / having problems?

Is it this one?, if so post a photo of the LEDs while running.

View attachment 79947

Radiators are bled, upstairs all hot but nothing downstairs. Inlet valves are warm but nothing getting into rads. All balanced 2 days ago and working fine.

How many rad? and is it a sealed or open vent system with a Feed&Expansion (small) Tank in the attic.

If a sealed system ensure that the system pressure is 1.5bar cold.

If a OV system, present setting of CC3 at 6.4M is too high IMO and can cause air ingress.

Suggest, in either case, c/o to constant pressure setting 2, CP2 which is 4.5M.

Press the setting button for ~ 3 secs until the yellow LED illuminates at the far right, then briefly press the button until the green LED and the yelloe LED next to it are also illuminated, you are now on CP2 at a constant 4.5M head.

(Also, these pumps have had more than their "fair" share of failures.)

If a sealed system ensure that the system pressure is 1.5bar cold.

If a OV system, present setting of CC3 at 6.4M is too high IMO and can cause air ingress.

Suggest, in either case, c/o to constant pressure setting 2, CP2 which is 4.5M.

Press the setting button for ~ 3 secs until the yellow LED illuminates at the far right, then briefly press the button until the green LED and the yelloe LED next to it are also illuminated, you are now on CP2 at a constant 4.5M head.

(Also, these pumps have had more than their "fair" share of failures.)

I think it is an open vent system. I have no way of setting system pressure and I know there is a small tank in the attic. We have 5 rads upstairs and 7 downstairs. I will follow your instructions and see how we get on. Cheers.How many rad? and is it a sealed or open vent system with a Feed&Expansion (small) Tank in the attic.

If a sealed system ensure that the system pressure is 1.5bar cold.

If a OV system, present setting of CC3 at 6.4M is too high IMO and can cause air ingress.

Suggest, in either case, c/o to constant pressure setting 2, CP2 which is 4.5M.

Press the setting button for ~ 3 secs until the yellow LED illuminates at the far right, then briefly press the button until the green LED and the yelloe LED next to it are also illuminated, you are now on CP2 at a constant 4.5M head.

(Also, these pumps have had more than their "fair" share of failures.)

- Messages

- 1,271

Pumps set too high and probably drawing air in, causing your downstairs circuit to air lock. The new Grunfos ones are more powerful than the old, you'll probably easily get away with I or II on the new model.

Thank you. Lights now flashing like in screenshot on Constant pressure 2. Should I restart system to deal with airlock downstairs?Pumps set too high and probably drawing air in, causing your downstairs circuit to air lock. The new Grunfos ones are more powerful than the old, you'll probably easily get away with I or II on the new model.

- Messages

- 1,271

Bleed any rads. Turn HW on, on it's own. Let it circulate round the HW system. When Hot and returning, turn HW off and CH on. Let upstairs rads get hot, when they're hot turn them all off and it should force it through to downstairs.Thank you. Lights now flashing like in screenshot on Constant pressure 2. Should I restart system to deal with airlock downstairs?View attachment 79951

See how you go on 2, if it keeps airlocking you may need to turn it down to 1.

When you have done the above go up to the attic and get someone to stop the boiler and watch and see if any spurt of water from the vent when the pump stops probably a few minutes after switching off the boiler, then get them to restart the boiler/pump and watch again for any pump over.

Thanks to both of you. Issue now sorted. You have been a massive help!!!Bleed any rads. Turn HW on, on it's own. Let it circulate round the HW system. When Hot and returning, turn HW off and CH on. Let upstairs rads get hot, when they're hot turn them all off and it should force it through to downstairs.

See how you go on 2, if it keeps airlocking you may need to turn it down to 1.

Glad you are sorted.

Some OV systems with the traditional V,C,P system still have problems with air ingress with a pump head > than say 3.5/4.0M that may be required for systems with a large number of rads or small bore piping can be "cured" by changing the above to a combined vent and cold feed like my 50 year old system (from new), I could run my system with one rad and still get no carry over at a pump head of 6M.

Some OV systems with the traditional V,C,P system still have problems with air ingress with a pump head > than say 3.5/4.0M that may be required for systems with a large number of rads or small bore piping can be "cured" by changing the above to a combined vent and cold feed like my 50 year old system (from new), I could run my system with one rad and still get no carry over at a pump head of 6M.

Attachments

Last edited:

Cheers. I am no plumber so much if that is like a different language. Sadly, it seems that as predicted CP2 might still be too much. Good heat last night, this morning but this evening after about 3 hours, I could hear a different 'tone' in the pump and once again the downstairs rads went cold. Trying to change to CP1 and go through same steps as last night. Bloody nightmare.Glad you are sorted.

Some OV systems with the traditional V,C,P system still have problems with air ingress with a pump head > than say 3.5/4.0M that may be required for systems with a large number of rads or small bore piping can be "cured" by changing the above to a combined vent and cold feed like my 50 year old system (from new), I could run my system with one rad and still get no carry over at a pump head of 6M.

This was the old pump. Was mostly on second speed but more recently 3.Its quite likely that you have a partial blockage where the cold feed joins the system, if you still have a problem at CP1 @ 3M then almost a certainty IMO. Any idea of the old pump (and setting).

This is what the pump was doing as I switched HW off.This was the old pump. Was mostly on second speed but more recently 3. View attachment 79992

Attachments

The pump was upside down so the picture I sent is after I have rotated itI'd say speed 3 was running at; at least a 5M head, can you check the direction of flow on the UPS3, if your system is something like the attachment, then the arrow on the pump should be pointing downwards.

Where is the arrow?The pump was upside down so the picture I sent is after I have rotated it

What do you mean by upside down? the pump label etc may be upside down but all that matters is that the arrow on the pump body is pointing in the correct direction.The pump was upside down so the picture I sent is after I have rotated it

Your picture is only darkness.

On the pump body, will send photo.Where is the arrow?

The picture of the old pump (blue) is rotated. The writing on it was upside down. It was the pump installed when the house was built.What do you mean by upside down? the pump label etc may be upside down but all that matters is that the arrow on the pump body is pointing in the correct direction.

Your picture is only darkness.

Yes, it is pointing downward

So, are you absolutely certain that the new pump is pumping in the same direction as the old one, ie, the arrow on the old pump was also pointing downwards??, Is you system as I showed above or can you post a photo of it?, its strange that you are getting problems at CP2 even though it is a bit high so CP1 may sort out the problem, was that system chemically cleaned or anything like that between pump changes?.

So, are you absolutely certain that the new pump is pumping in the same direction as the old one, ie, the arrow on the old pump was also pointing downwards??, Is you system as I showed above or can you post a photo of it?, its strange that you are getting problems at CP2 even though it is a bit high so CP1 may sort out the problem, was that system chemically cleaned or anything like that between pump changes?.

This is the old pump and if it appears you will see what I mean by upside down. I don't have any other image so can only presume the British gas engineer who put the new one in ensured it is pumping on same direction. No chemical cleaning I am aware of.

Well you will have to be happy (ensured) that the UPS3 is pumping in the correct direction before taking any drastic or unnecessary action, if the pipe coming out of the bottom of the pump then goes to either a three way valve or to a number of valves (all/any of which will have a motor with a cable) then pump direction is downwards, if these valve(s) come off the top pipe then the pump must pump upwards.

Yes, that's where the 3 port valve isWell you will have to be happy (ensured) that the UPS3 is pumping in the correct direction before taking any drastic or unnecessary action, if the pipe coming out of the bottom of the pump then goes to either a three way valve or to a number of valves (all/any of which will have a motor with a cable) then pump direction is downwards, if these valve(s) come off the top pipe then the pump must pump upwards.

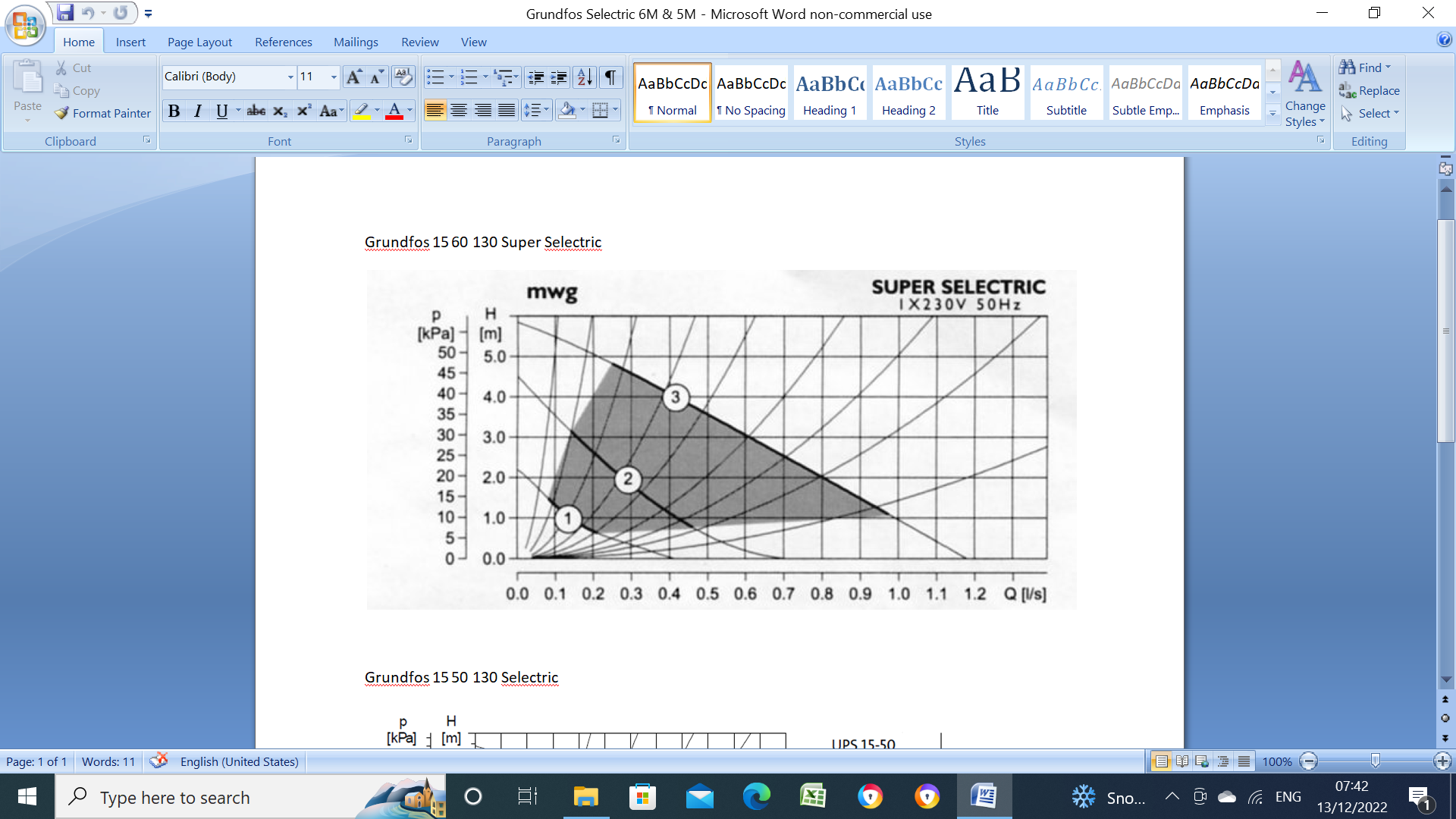

Your old pump was probably a 6M Selectric (made in 2007) so the pump curves may look like this. If so then even speed 3 has a relatively low head of 2.5m at 0.7ms/hr and hopefully CP1 or PP3 will also not cause any pumpover problems.

Last edited:

Reply to Any ideas? Unreliable heating. in the Central Heating Forum area at PlumbersForums.net

Similar plumbing topics

Hi, Can anyone advise as to why the cold water to my bathroom keeps airlocking?

This originally happened about 12 months ago and has happened 3-4 times since.

It’s an upstairs bathroom, fed from a tank in the attic. The tank is about 8 Meters away and feeds a bath, sink and toilet. The tank...

- Replies

- 9

- Views

- 324

The fittings below are for a mixer bar attached to a self contained shower. i.e not a wall. The attaching screws have snapped. I could get two new brackets, dismantle that existing one and start again or I could try and re attach via those screws, removing the broken ones from the plate and wall...

- Replies

- 1

- Views

- 200

Creating content since 2001. Untold Media.

Newest Plumbing Threads

-

Cistern filling one third of the way

- Started by dwaindigital

- Replies: 2

-

Boiler losing pressure only on central heating

- Started by SnosRap75

- Replies: 2

-

tanking. Is it ok to just seal everything with plastic.

- Started by Staggersandfalls

- Replies: 3

-

Pop quiz, does anyone recognise this radiator valve?

- Started by dimuc

- Replies: 3

-

SUsing coil to clear pipe leading to gutter

- Started by Sonya K

- Replies: 1

-

Replacing outdoor P-Trap Gully with Bottle Gully

- Started by DIwhYdidIstartThis

- Replies: 0

-

-

-

-

-

Mixer mixer shower, compatible with tanked supply

- Started by Matt0029

- Replies: 2

-

-

No Hot water, Fixed and Broken Again Ideal Logic 24

- Started by Filthbags

- Replies: 2

-

-

What's happening to this radiator, paint flaking off?

- Started by mikmikmikmik2024

- Replies: 3