You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Thread starter sherylryan

- Start date

- Replies 171

- Views 10K

- Copy link Copy link

Discuss What size boiler needed in the Central Heating Forum area at PlumbersForums.net

- Messages

- 137

Yes expansion valve on HW cylinder was dripping, with that bypass valve open hot water was feeding down the pipe to where the EV is on cylinder. Nothing else was calling for heat other than Kitchen UFH with manual bypass open. Boiler pressure was 1.5 bar, pump was 1.35 bar, flow temp was 72 degrees. (Hope that makes sense)Do you mean the expansion valve on the HW cylinder is dripping, if so, this, or a failing HW cylinder EV has got nothing to do with the boiler EV or PRV, what is/was the boiler pressure gauge reading when this dripping occurs?.

Another question, our original nozzle was a .65 80 s 2.47kg/h, if I'm reading these specs correct on the side of the burner does it indicate the nozzle size must be 2.8 - 4.5 kg/h and is the output of this burner 33-54 kw, should it couldn't be downsized to a 26kw?

Attachments

Last edited:

If that bypass valve is feeding HOT water into the HW cylinder then it will have to be from the HW cylinder hw outlet which will be at higher pressure when the cylinder is heating or is hot with no HW draw off, if tied into the boiler system primary system flow pipe it cannot feed hw as the primary/boiler system pressure is only 1.5bar. If it was connected from the cold mains then that will lift the cylinder expansion valve but the pipe would be cold.?

Nozzle Sizing: From below. a 0.65 nozzle will give a burner output of 31kw @ 12.5bar which will be 31*(14/12.5)^2, 32.81kw @ 14bar, a boiler output of 28.87kw @ 88% boiler efficiency.

Your present 0.55?? nozzle will give a burner output of 26kw @ 12.0bar which will be 26*(14/12.0)^2, 28.10kw @ 14bar, a boiler output of 24.73kw @ 88% boiler efficiency.

Nozzle Sizing: From below. a 0.65 nozzle will give a burner output of 31kw @ 12.5bar which will be 31*(14/12.5)^2, 32.81kw @ 14bar, a boiler output of 28.87kw @ 88% boiler efficiency.

Your present 0.55?? nozzle will give a burner output of 26kw @ 12.0bar which will be 26*(14/12.0)^2, 28.10kw @ 14bar, a boiler output of 24.73kw @ 88% boiler efficiency.

Attachments

- Messages

- 137

Ok so you get a burner output and a boiler output from one nozzle calculations?If that bypass valve is feeding HOT water into the HW cylinder then it will have to be from the HW cylinder hw outlet which will be at higher pressure when the cylinder is heating or is hot with no HW draw off, if tied into the boiler system primary system flow pipe it cannot feed hw as the primary/boiler system pressure is only 1.5bar. If it was connected from the cold mains then that will lift the cylinder expansion valve but the pipe would be cold.?

Nozzle Sizing: From below. a 0.65 nozzle will give a burner output of 31kw @ 12.5bar which will be 31*(14/12.5)^2, 32.81kw @ 14bar, a boiler output of 28.87kw @ 88% boiler efficiency.

Your present 0.55?? nozzle will give a burner output of 26kw @ 12.0bar which will be 26*(14/12.0)^2, 28.10kw @ 14bar, a boiler output of 24.73kw @ 88% boiler efficiency.

In below photo, pipes in red were hot, pipe going into EV was cold

Yes, the table gives (presumably) burner output, the only assumption that will marginally affect the boiler output is its efficiency so 85% to 92% should cover it, the calculation for pressure is universally used, ie flow is prop to the sq.root of pressure, I should have shown that as ^0.5 and not ^2, but I did use ^0.5 in the calculation.

Can't really comment on that by pass except to suggest finding out exactly where the connections are teed in.

Can't really comment on that by pass except to suggest finding out exactly where the connections are teed in.

- Messages

- 137

Thank you for the calculations they are very handy.Yes, the table gives (presumably) burner output, the only assumption that will marginally affect the boiler output is its efficiency so 85% to 92% should cover it, the calculation for pressure is universally used, ie flow is prop to the sq.root of pressure, I should have shown that as ^0.5 and not ^2, but I did use ^0.5 in the calculation.

Can't really comment on that by pass except to suggest finding out exactly where the connections are teed in.

I am totally stumped over the whole system

but have quite a bit more knowledge now thanks to you.

but have quite a bit more knowledge now thanks to you.This Laundry Manifold/TMV is a mystery to me as all the indications are that the return temperature to the boiler is the mixed flow temperature but havn't figured out if this is thermodynamically possible.

You might please take the (4) temperatures where indicated and also take the return temperature to the boiler; at the boiler.

You might please take the (4) temperatures where indicated and also take the return temperature to the boiler; at the boiler.

Attachments

Last edited:

- Messages

- 137

Ok, will do. I’ll get back to you.This Laundry Manifold/TMV is a mystery to me as all the indications are that the return temperature to the boiler is the mixed flow temperature but havn't figured out if this is thermodynamically possible.

You might please take the (4) temperatures where indicated and also take the return temperature to the boiler; at the boiler.

View attachment 76807

- Messages

- 137

Boiler set point 60This Laundry Manifold/TMV is a mystery to me as all the indications are that the return temperature to the boiler is the mixed flow temperature but havn't figured out if this is thermodynamically possible.

You might please take the (4) temperatures where indicated and also take the return temperature to the boiler; at the boiler.

View attachment 76807

Boiler flow temp 72

Boiler return 59

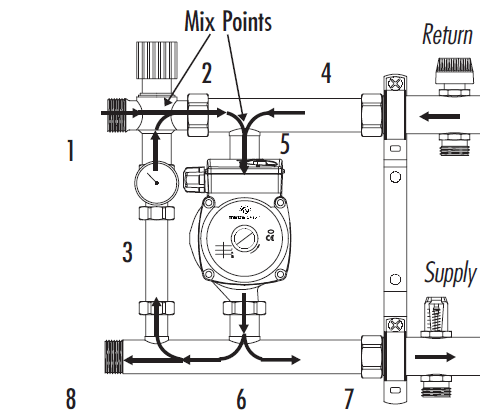

Ufh at points 2 72 into mixing valve 50 going into pump.

Point 4 45 degrees

Point 8 57 degrees

Wow temps are all over the place. Return is high into boiler as that manual bypass is open.

I have attached a graph of the laundry manifold with boiler flor and return temps taken when boiler was set at 35kw. (Blue is boiler firing flow , Red is pump only pumping)

- Messages

- 137

Oh sorry, I’ll check againSorry for confusing you, its the temperatures at 1,2,3&4 in this attachment I would like.

- Messages

- 137

Oh sorry,Sorry for confusing you, its the temperatures at 1,2,3&4 in this attachment I would like.

Awesome, sorry have been away for back tomorrow and then I’ll have temps. Thank you.Have added another one below, point 5, so measurements at points 1,2,3,4,5. (thanks for your patience)

- Messages

- 137

Ok so I have checked all temperatures and what a shambles, they areOh sorry,

Awesome, sorry have been away for back tomorrow and then I’ll have temps. Thank you.

Boiler flow 76.5 degrees

Boiler Return 46.3

Temp 1 - 60

Temp 2 - 46

Temp 3 - 38

Temp 4 - 34

Temp 5 - 48

Yes, it's working as I thought it might, apart from temp 1 at 60C which should be the same as the boiler flow at 76.5C or vica versa. The TMV is controlling (first mixing) the temp at 48C = temp 5, this is then (second) mixing with the manifold return of 34C to give a final mixed manifold temperature of 38C, there is only a dT of 4C across the loops so do your calc, LPM*60*dT/860, to give the loop output, kw.

The TMV mixed flow temp of 48C is returning to the boiler which is very good from a balanced corrosion and efficiency point of view, obviously if you require the manifold flow temp of 38c increased then you have to increase the TMV setting.

Its quite a clever control system IMO especially for a oil fired system as it obviates the need for recirculation if the manifold return was returned to the boiler.

The TMV mixed flow temp of 48C is returning to the boiler which is very good from a balanced corrosion and efficiency point of view, obviously if you require the manifold flow temp of 38c increased then you have to increase the TMV setting.

Its quite a clever control system IMO especially for a oil fired system as it obviates the need for recirculation if the manifold return was returned to the boiler.

Reply to What size boiler needed in the Central Heating Forum area at PlumbersForums.net

Similar plumbing topics

- Replies

- 2

- Views

- 613

- Replies

- 3

- Views

- 575

P

- Replies

- 15

- Views

- 2K

Newest Plumbing Threads

-

How can I check if my pressure pump is working ?

- Started by Jackrawlings

- Replies: 0

-

-

-

-

What's the most convenient way for me to plumb drainage channel?

- Started by Instadeth

- Replies: 4

-

-

Y Plan central heating gets hot on hot water demand

- Started by MPGASANDPLUMBING

- Replies: 2