More expensive based on a higher tank temp to maintain.

Cant see how a tank temp of 60 to 65 will deliver satisfactory dhw performance.

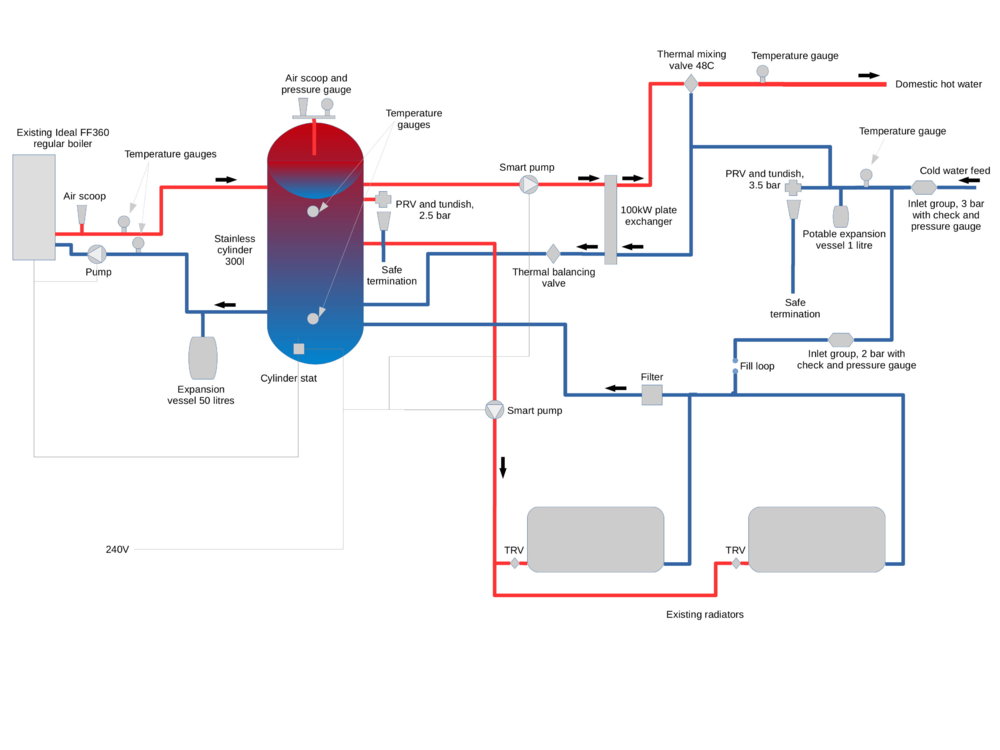

This is the reason for the 100kW plate exchanger, rather than an internal coil, which will allow the tank to run at a lower temperature.

But you are correct in that one would expect tank losses to be bigger, because the tank is bigger than an unvented would be. For the tank, exchanger, and piping losses, I am planning to insulate them well to reduce this, and to upgrade the insulation in the house in general.

With my current boiler it will very likely cost less to run, as it will stop the boiler cycling in the period after the rads warm up, but before the room thermostat cuts out.

[automerge]1578579156[/automerge]

You can calculate the theoretical efficiency of your system once you know all the loads and heat loss factors. Generally, to improve efficiency you minimise heat transfer and deliver the heat to point of use as soon as it is created. The concept of a thermal store is to store energy that you would otherwise loose. With a gas fired boiler (even on older one) you have extensive flexibility on control - so you only produce heat when you need it and immediately deliver it to where you need it. To produce heat from a gas fired boiler to store (in a small domestic situation) is just odd.

By this logic we should use instantaneous gas waters heaters all round, for example combis. The flaw there is that they don't cope well with variable demand, and any efficiency gained from reducing tank losses is often lost. I would bet in a real world situation, unventeds are more efficient than combi's for this reason, unless they have a decent sized tank, and then they become an unvented. Think how many times you turn the hot tap on and off when you are cooking.

As a starting point for your proposed system, you will use just under 20kw to heat your store / buffer to 65 degrees ( assuming a 10 degree inflow temperature). Thereafter, around an hour, your system will start to perform as you have designed it.

With respect to the plate heat exchanger for DHW you would normally configure it to take the primary flow from the heat source and the secondary to the buffer vessel. You also don’t normally specify them in Kw. You establish the required flow rate, determine your maximum flow, duration of max flow and your input flow and return temperature requirements. That then determines the gross output of the exchanger against the specific flow criteria. The flow criteria for a heat exchanger to work is absolutely key.

To give you an order of magnitude, in very simple terms, a 35kw gas fired combi uses a 30 to 40kw exchanger (configured to the boiler flow criteria) to deliver DHW. At best, your proposed system is starting with less than 20kw of energy to input into the exchanger, with a falling flow temperature.

All plate exchangers I have seen are rated in kW, and that is for a 40C delta. In this case it will be more like 15C, so I calculated how many watts to heat water from 5C-45C based on 12 litres/minute flow, multiplied by 3, and padded it a little for insurance. Do you think I have made a mistake, and 100kW is too small?

Sometimes, when you get a really good idea it is useful to ask yourself why other people are not doing it. I don’t mean that to be rude,

but it is a useful exercise to draw you back to reality.

I believe this is one of the standard ways to set up a thermal store, aside from the balancing valve and smart pump instead of a flow switch, that is indeed an experiment.

I don’t want to be Dr Doom and spoil your fun in developing such a system, but a new gas fired combi will be a lot more efficient, probably cheaper to install and give you a consistent flow of hot water.

No worries, I asked for criticism. I have space for a cylinder, so I am not limited to a combi, although it most certainly would be cheaper.

I did install the exact same system in a previous house, except it used an internal coil for DHW rather than a plate exchanger. Until you have lived in a house with a buffered heating system it is hard to understand the comfort you are missing. No cycling of room or radiator temperatures when the thermostat cuts in an out, heat always there, much easier to control individual room temperature, no boiler cycling, etc. It is very pleasant.