Morning,

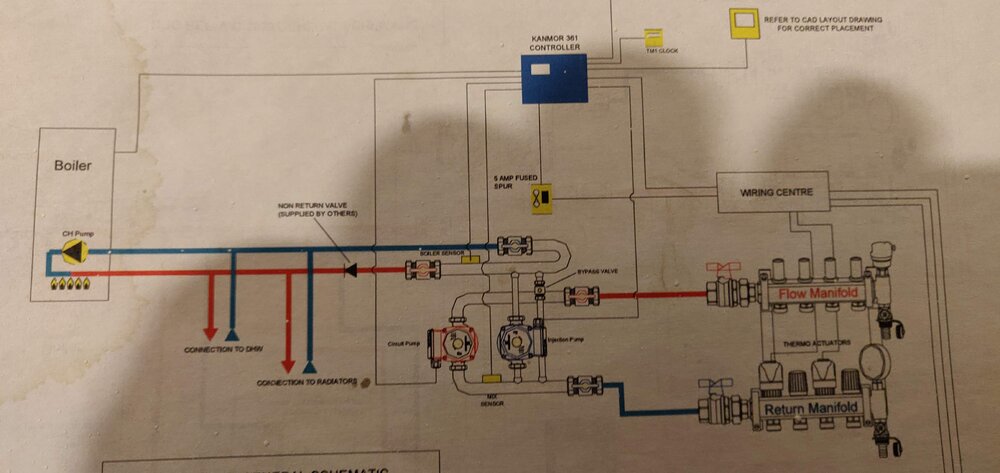

The pumps should be pumping as you have indicated John, and the circled valve is indeed the manual bypass. The problem as I understand it is that if the manual bypass will push the same volume of water back into the primary loop as the pump injects out of it. I've fiddled with this and I can get hot water down to the injector pump but only when the flow back to the primary loop is massively restricted. If I open up the bypass essentially the cold water pushes back past the t junction where the injector pump branches off, and all that happens is that the cold water gets re-injected into the UFH. I've found some old schematics, and the picture of my manifold is there (actuators taken off as I wanted to make sure none of those were causing flow to stop).

The pumps should be pumping as you have indicated John, and the circled valve is indeed the manual bypass. The problem as I understand it is that if the manual bypass will push the same volume of water back into the primary loop as the pump injects out of it. I've fiddled with this and I can get hot water down to the injector pump but only when the flow back to the primary loop is massively restricted. If I open up the bypass essentially the cold water pushes back past the t junction where the injector pump branches off, and all that happens is that the cold water gets re-injected into the UFH. I've found some old schematics, and the picture of my manifold is there (actuators taken off as I wanted to make sure none of those were causing flow to stop).