Yes, regarding the UFH heating requirements and boiler output, both will (have to) be the same. With your system if you want to run at a manifold flowtemp of 40C then you would have to reduce the boiler flowtemp to 59C to give the original 27C boiler dT, normally, you would have a separate UFH manifold recirc pump on each UFH system, then the boiler dT can be controlled to whatever you require irrespective of boiler or manifold temperatures but if your system is working OK then why worry as it certainly wont require more energy and is actually more efficient with those very low return temperatures.

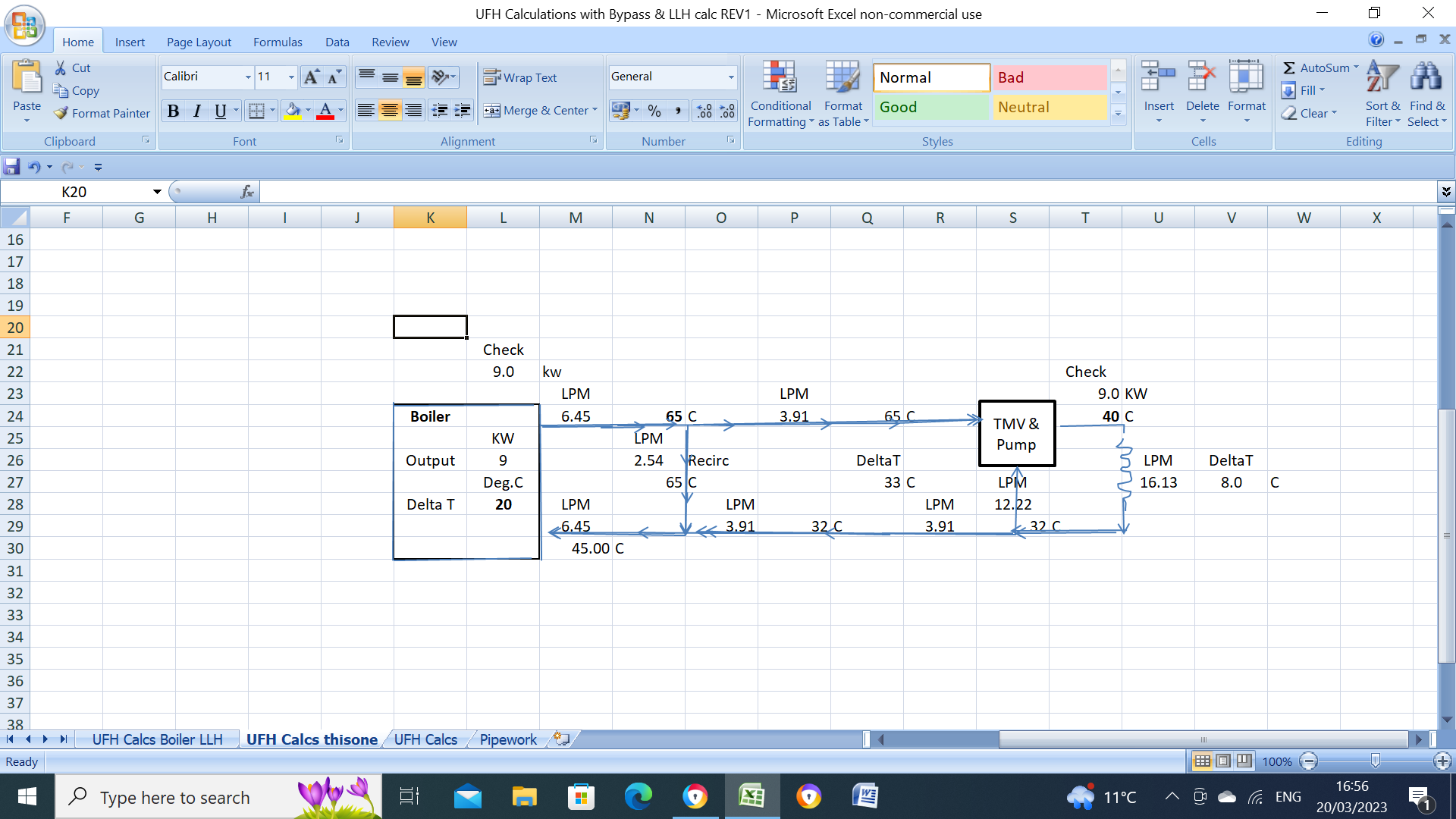

See below schematic of a system with a LLH and UFH manifold recirc pump but with a boiler flowtemp of 65C and UFH flowtemp of 40C and (if) a required boiler dT of 20C, the boiler return will now be 45C.

See below schematic of a system with a LLH and UFH manifold recirc pump but with a boiler flowtemp of 65C and UFH flowtemp of 40C and (if) a required boiler dT of 20C, the boiler return will now be 45C.