There's a bit of a delay as my posts seem to take an age to get through moderation (probably because I'm new). The actuators have been taken off to make sure that I was getting flow everywhere. The Alpha 2L injector is supposed to be controlled by the Kanmor 361 controller box. I've fiddled with it again and managed to persuade a little hot water to come down through the pipe to the injector, but I was hoping that swapping the bypass valve to an auto bypass might have been the answer, looks like it might be a bit more costly!!

-

NavigationPlumbing Advice Forums UK Plumbers Forums USA Plumbing Advice Australia Plumbers Talk Canada Plumbing Zone Forum Ireland Plumbing Advice

Bathrooms, Showers And Wetrooms DIY Plumbing Advice Plumbing Courses Water Underfloor Heating Advice Plumbing Tools Renewables Plumbing Zone Commercial and Industrial Plumbing Forum Specialist Plumbing Forum Oil And Solid Fuel Forum G3 Unvented Forum

Gas Engineers Advice Central Heating Forum Gas Engineers Forum

PF Community Forums Welcome Forum Plumbing News General Chat

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Discuss Mixing Pressure Problems in the Central Heating Forum area at PlumbersForums.net

No it's not much use as it is at all. The problem is that the bloke who built the house used non standard parts for everything, from the boiler to the manifolds. I've just had a good read of the pack and need to change some settings on the mixer controls... You never know, it can't do any harm!

[automerge]1606689787[/automerge]

I think I've got it sussed. Checked the system and there are 2, 2 zone part valves going to the DHW and primary loop. When the system calls for DHW the boiler loop loses pressure and the cold water from the UFH pushes back into the primary loop via the bypass. When the valve opens to supply hot water back to the primary loop, the hot water struggles to overcome the pressure of the cold water coming back through the bypass and can't reach the injector pump. If I play with restricting the manual valve I can usually resume the flow of hot water to the injector but it's very sensitive. I think If I replace the manual valve with an auto valve and then rebalance it might solve the problem..... Well here's hoping (and I hope that all makes sense as I'm a science teacher and not a heating engineer and before Monday knew nothing at all about UFH systems!).

[automerge]1606689787[/automerge]

I think I've got it sussed. Checked the system and there are 2, 2 zone part valves going to the DHW and primary loop. When the system calls for DHW the boiler loop loses pressure and the cold water from the UFH pushes back into the primary loop via the bypass. When the valve opens to supply hot water back to the primary loop, the hot water struggles to overcome the pressure of the cold water coming back through the bypass and can't reach the injector pump. If I play with restricting the manual valve I can usually resume the flow of hot water to the injector but it's very sensitive. I think If I replace the manual valve with an auto valve and then rebalance it might solve the problem..... Well here's hoping (and I hope that all makes sense as I'm a science teacher and not a heating engineer and before Monday knew nothing at all about UFH systems!).

Last edited:

Despite our reservations, it is certainly a very interesting challenge. logically, one would think that it should work in some fashion or other, if not perfectly, some design guru went to the trouble of putting this package together with the Kanmor 361 and the injection pump etc, if you have any links to its setting up you might post them.

Re the injection pump control which is one of the key components, the speed/frequency is controlled by the Kanmor but this is only designed for the older type of circ pumps (see quote) some of the newer types can be externally controlled, but only by a PCM (pulse width modulation) signal which is plugged into the pump motor. I wonder was your injection pump changed out sometime for the present Alpha 2L which cannot be speed controlled IMO by the Kenmor.

Quote:

HVAC Systems

The Mixing Control 361 is designed to operate a mixing pump using Outdoor Temperature Reset. It can be used in applications ranging from in-floor radiant to commercial baseboard systems for Boiler Return Protection with full reset. This control regulates a single heating water temperature through Mixing Outdoor Reset. It provides mixing by speeding up or slowing down a single permanent capacitor (standard wet rotor) circulator, and provides control of the mix system pump. Unquote.

Re the injection pump control which is one of the key components, the speed/frequency is controlled by the Kanmor but this is only designed for the older type of circ pumps (see quote) some of the newer types can be externally controlled, but only by a PCM (pulse width modulation) signal which is plugged into the pump motor. I wonder was your injection pump changed out sometime for the present Alpha 2L which cannot be speed controlled IMO by the Kenmor.

Quote:

HVAC Systems

The Mixing Control 361 is designed to operate a mixing pump using Outdoor Temperature Reset. It can be used in applications ranging from in-floor radiant to commercial baseboard systems for Boiler Return Protection with full reset. This control regulates a single heating water temperature through Mixing Outdoor Reset. It provides mixing by speeding up or slowing down a single permanent capacitor (standard wet rotor) circulator, and provides control of the mix system pump. Unquote.

Indeed it was...... I'm off to work, but I'll post settings when I get home.Despite our reservations, it is certainly a very interesting challenge. logically, one would think that it should work in some fashion or other, if not perfectly, some design guru went to the trouble of putting this package together with the Kanmor 361 and the injection pump etc, if you have any links to its setting up you might post them.

Re the injection pump control which is one of the key components, the speed/frequency is controlled by the Kanmor but this is only designed for the older type of circ pumps (see quote) some of the newer types can be externally controlled, but only by a PCM (pulse width modulation) signal which is plugged into the pump motor. I wonder was your injection pump changed out sometime for the present Alpha 2L which cannot be speed controlled IMO by the Kenmor.

[automerge]1606731305[/automerge]

AddDespite our reservations, it is certainly a very interesting challenge. logically, one would think that it should work in some fashion or other, if not perfectly, some design guru went to the trouble of putting this package together with the Kanmor 361 and the injection pump etc, if you have any links to its setting up you might post them.

Re the injection pump control which is one of the key components, the speed/frequency is controlled by the Kanmor but this is only designed for the older type of circ pumps (see quote) some of the newer types can be externally controlled, but only by a PCM (pulse width modulation) signal which is plugged into the pump motor. I wonder was your injection pump changed out sometime for the present Alpha 2L which cannot be speed controlled IMO by the Kenmor.

Quote:

HVAC Systems

The Mixing Control 361 is designed to operate a mixing pump using Outdoor Temperature Reset. It can be used in applications ranging from in-floor radiant to commercial baseboard systems for Boiler Return Protection with full reset. This control regulates a single heating water temperature through Mixing Outdoor Reset. It provides mixing by speeding up or slowing down a single permanent capacitor (standard wet rotor) circulator, and provides control of the mix system pump. Unquote.

I've got the full plumber/electrician pack with all the settings. We might get this thing figured out eventually. John you seem to know a lot about the pumps (of which I know nothing), do you think that maybe changing the Alpha's setting might help in the short term?Indeed it was.... I'm off to work, but I'll post settings when I get home.

Last edited:

It may but last night I was looking at the system schematic and can't figure out why the injection pump inlet is taken from the boiler return (NRV in boiler flow), this means that if no demand for DHW or radiators that the injection pump, is fighting the boiler circ pump (which is on the return), very UNlikely designed that way, have another good look at the arrow on the injection pump which may be pointing upwards, the pump would then be returning cold water to the boiler but then there would need to be (probably controlled ) a hot water supply to the UFH main manifold somewhere, if you look at the schematic which includes the DHW cylinder you will see some form of controller that looks a bit like a pump but is probably a controller as it seems to be wired into the kanmor? high up in the drawing, can you identify this as well this evening.

Attachments

Last edited:

Right then John what do you want?

[automerge]1606760051[/automerge]

The only thing missing from the schematic is the outdoor sensor which I think that the unit uses to calculate the flow need to keep the house at a certain temperature. I've also changed the alpha pump settings to lowest constant flow (I) and that seems to be letting the hot water flow through from the primary circuit.

As for the flow, here's my hypothesis:

The primary circuit has two junctions, the first is the intake and the second the return flow. I'm assuming that if the pressure of the return flow is greater than that of the primary the hot water will take the path of least resistance and flow downwards to the injector pump. This seems to be what's happening in practise, as if the return flow is too fast the hot water never gets to the t junction. If it's too slow, the injector doesn't allow any water to be injected which could be due to the incompressible nature of the ufh circuit, or just because the path of least resistance is forwards rather than down.... (I need a degree in fluid dynamics for this one!)

[automerge]1606760051[/automerge]

The only thing missing from the schematic is the outdoor sensor which I think that the unit uses to calculate the flow need to keep the house at a certain temperature. I've also changed the alpha pump settings to lowest constant flow (I) and that seems to be letting the hot water flow through from the primary circuit.

As for the flow, here's my hypothesis:

The primary circuit has two junctions, the first is the intake and the second the return flow. I'm assuming that if the pressure of the return flow is greater than that of the primary the hot water will take the path of least resistance and flow downwards to the injector pump. This seems to be what's happening in practise, as if the return flow is too fast the hot water never gets to the t junction. If it's too slow, the injector doesn't allow any water to be injected which could be due to the incompressible nature of the ufh circuit, or just because the path of least resistance is forwards rather than down.... (I need a degree in fluid dynamics for this one!)

Last edited:

Arrow is definitely pointing down. Pages as requested, but I don't know what I've done but the mix temperature is going up. It's at 27 now and rising and it's never been above 21. Basically I put the alpha on (I) waited until primary was sending warm back to the boiler, changed to the pump up to highest constant and it seems like it's working

[automerge]1606763805[/automerge]

Just checked again and it's back to 24 but progress.... I suppose it's proof of concept at least.

[automerge]1606763805[/automerge]

Just checked again and it's back to 24 but progress.... I suppose it's proof of concept at least.

Attachments

Last edited:

Thanks but can't read the attachments.

What do you mean by

" waited until primary was sending warm back to the boiler "

Is/was the CH or/and the HW on while taking these tests?

Can you see what that item is in the picture showing the cylinder, above. (post 21)

I honestly cannot see that system working as is with the NRV installed where it is and without the CH or HW on as well, at best then IMO, the injector pump will take some of the cooled water returning from the rads/cylinder coil and inject it into the manifold but that temperature is completely dependent on that return temperature which may be even lower than the required UFH temperature, also the "bypass" is stationed far too close to the injector pump to give any real temperature or contra flows separation.

Can you have a quick read through those pages and see what commissioning problems they had and a explanation of how the system is supposed to work.

Taking the injected water supply from between the NRV and the boiler would definitely make some bit of sense as it is then hot injected water at a set (boiler) temperature.

What do you mean by

" waited until primary was sending warm back to the boiler "

Is/was the CH or/and the HW on while taking these tests?

Can you see what that item is in the picture showing the cylinder, above. (post 21)

I honestly cannot see that system working as is with the NRV installed where it is and without the CH or HW on as well, at best then IMO, the injector pump will take some of the cooled water returning from the rads/cylinder coil and inject it into the manifold but that temperature is completely dependent on that return temperature which may be even lower than the required UFH temperature, also the "bypass" is stationed far too close to the injector pump to give any real temperature or contra flows separation.

Can you have a quick read through those pages and see what commissioning problems they had and a explanation of how the system is supposed to work.

Taking the injected water supply from between the NRV and the boiler would definitely make some bit of sense as it is then hot injected water at a set (boiler) temperature.

Last edited:

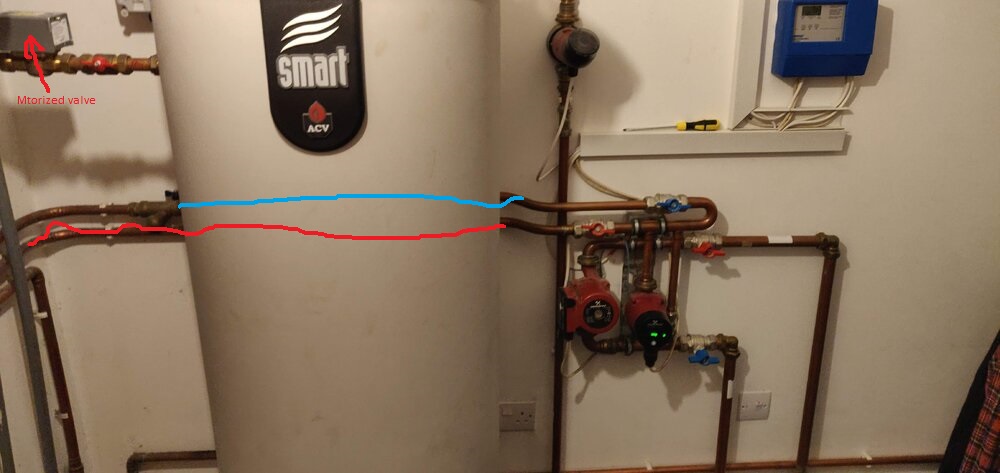

I've tried to annotate the picture to label each item.

Hope this makes a bit of sense.

[automerge]1606770384[/automerge]

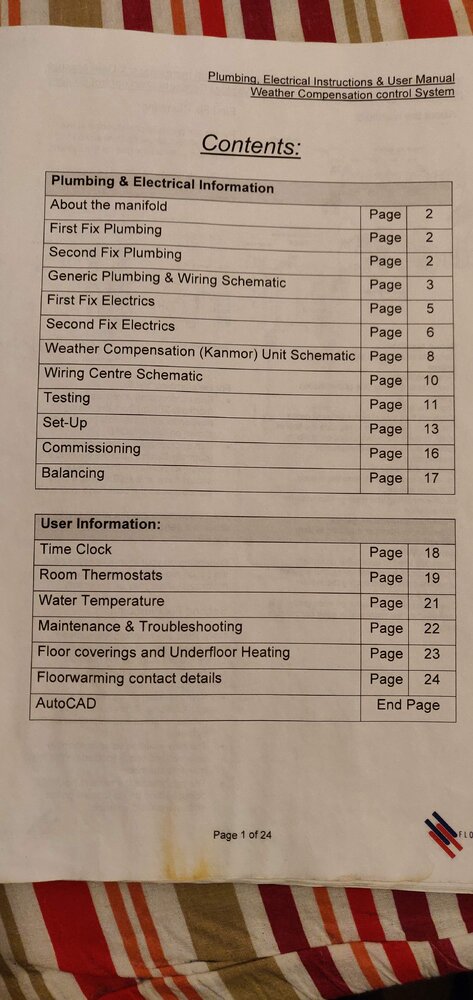

Here's the scanned pages.

Hope this makes a bit of sense.

[automerge]1606770384[/automerge]

[automerge]1606770875[/automerge]Thanks but can't read the attachments.

What do you mean by

" waited until primary was sending warm back to the boiler "

I just meant that I restricted water flow through bypass so that the return to the boiler heated up.

Is/was the CH or/and the HW on while taking these tests?

I hadn't switched anything off

Can you see what that item is in the picture showing the cylinder, above. (post 21)

Wasn't sure what you meant so I annotated the original photo

I honestly cannot see that system working as is with the NRV installed where it is and without the CH or HW on as well, at best then IMO, the injector pump will take some of the cooled water returning from the rads/cylinder coil

No rads and cylinder coil has its own NRV as shown

and inject it into the manifold but that temperature is completely dependent on that return temperature which may be even lower than the required UFH temperature, also the "bypass" is stationed far too close to the injector pump to give any real temperature or contra flows separation.

The contra flow separation proximity is what I thought the problem was.

Can you have a quick read through those pages and see what commissioning problems they had and a explanation of how the system is supposed to work.

Taking the injected water supply from between the NRV and the boiler would definitely make some bit of sense as it is then hot injected water at a set (boiler) temperature.

Here's the scanned pages.

Attachments

Last edited:

Can you take a snapshot on the left around where I have continued the red line showing the pipework layout, in particular any NRV (the ones you showed are motorized zoning valves)

Read the Tap scanned pages, the most important item now is to see where (if) this NRV is.

Read the Tap scanned pages, the most important item now is to see where (if) this NRV is.

Last edited:

I think that's about as clear as you can get it, there isn't a NRV between the T off for the HW cylinder coil and the motorised UFH zoning valve so that means that the hot water is supplied to the UFH once its opened despite the original drawing showing one, I wonder why?.

So, as you said the proximity of the injection pump and by pass vale is the main problem although I find it inexplicable that a system would be designed this way... it may work if mods made as in attachment, I don't see any reason to have the hot & cold looped as this only creates a full fledged by pass once the UFH zone valve is opened, also the original injection pump was a standard pump which can be speed controlled.

So, as you said the proximity of the injection pump and by pass vale is the main problem although I find it inexplicable that a system would be designed this way... it may work if mods made as in attachment, I don't see any reason to have the hot & cold looped as this only creates a full fledged by pass once the UFH zone valve is opened, also the original injection pump was a standard pump which can be speed controlled.

Last edited:

Thanks again John,

I've restricted the flow on the bypass valve and turned the Alpha down to constant setting (II). I'll see if that's enough flow to get at least a little bit of heat into the system. I was also wondering if an auto bypass valve might help.

As you know a bit about pumps do you think this one would be suitable as the documentation says that the original was a grundfos 15-50.

I just can't find out if it's controllable.

I'll speak to my heating engineer and see if he can make the relevant changes (although he's the one who put the alpha on!).

Thanks once again for your help with this enigma! One day I will get it to function correctly

I've restricted the flow on the bypass valve and turned the Alpha down to constant setting (II). I'll see if that's enough flow to get at least a little bit of heat into the system. I was also wondering if an auto bypass valve might help.

As you know a bit about pumps do you think this one would be suitable as the documentation says that the original was a grundfos 15-50.

https://www.NoLinkingToThis/p/grund...5zoyb7cPKrGg5KEHDWkaAqQ8EALw_wcB&gclsrc=aw.ds

I just can't find out if it's controllable.

I'll speak to my heating engineer and see if he can make the relevant changes (although he's the one who put the alpha on!).

Thanks once again for your help with this enigma! One day I will get it to function correctly

Reply to Mixing Pressure Problems in the Central Heating Forum area at PlumbersForums.net

Similar plumbing topics

Newest Plumbing Threads

-

looking for some ACS mock/past paper, can anyone help?

- Started by tsxho0526

- Replies: 0

-

JDrainage camera faults and where to fix?

- Started by Jenevora Murray-Forman

- Replies: 0

-

-

-

-

-

SAdvice on moving toilet from front of house to the back.

- Started by Steve F

- Replies: 0