Hello

new to the forum so will say thank you in advance to all and any assistance you can provide.

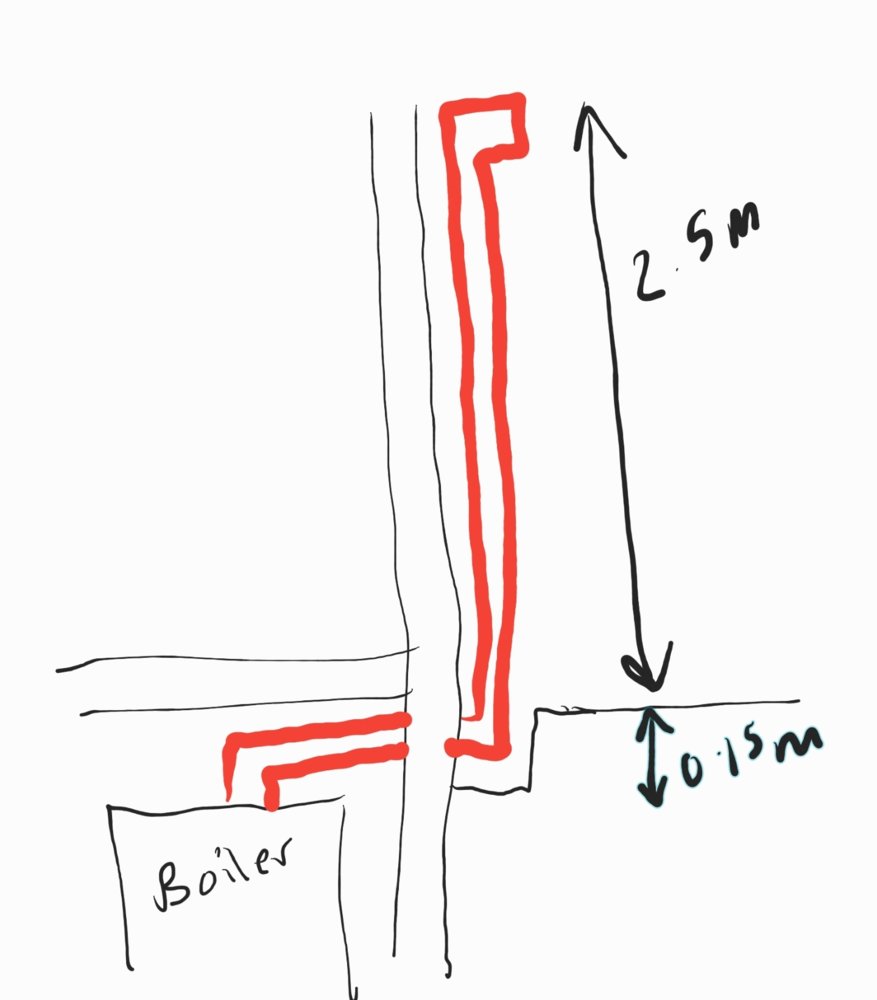

background: current boiler installed in Basement in 2011. Six months ago it failed gas safety for the first time, I sought a second opinion and same thing. Diagnosis being that the flue termination is too close to the ground.

Nothing has changed re the setup so I’m not going to get bogged down in why it was fine and now it isn’t,the regs are the regs.

after a bit of googling I’m confused about the rules that govern this, in particular definitions of the terminology. I know flue clearance must be 300mm from the ground but clearance of what? My logic would have thought the outlet of the flue ie where the gases escape (which is 2.5m from ground) but can only assume my setup is failing because it covers the height the piping exits the property at the horizontal (at 0.15m above a dug out area that enables circulation for an airbrick into the basement)

if it is in fact 300m from where the pipe simply exits the property (even if not terminated there) what are my options?

1) does increase the depth of the dug out area to increase the distance from it to the horizontal to 300mm suffice (even if still below adjacent “normal” ground level)

2) drill through room above and take flue further vertical so it doesn’t exit the property horizontally until 300mm above normal ground level

3) anything else?

once again appreciate any advice you can give

Thanks

new to the forum so will say thank you in advance to all and any assistance you can provide.

background: current boiler installed in Basement in 2011. Six months ago it failed gas safety for the first time, I sought a second opinion and same thing. Diagnosis being that the flue termination is too close to the ground.

Nothing has changed re the setup so I’m not going to get bogged down in why it was fine and now it isn’t,the regs are the regs.

after a bit of googling I’m confused about the rules that govern this, in particular definitions of the terminology. I know flue clearance must be 300mm from the ground but clearance of what? My logic would have thought the outlet of the flue ie where the gases escape (which is 2.5m from ground) but can only assume my setup is failing because it covers the height the piping exits the property at the horizontal (at 0.15m above a dug out area that enables circulation for an airbrick into the basement)

if it is in fact 300m from where the pipe simply exits the property (even if not terminated there) what are my options?

1) does increase the depth of the dug out area to increase the distance from it to the horizontal to 300mm suffice (even if still below adjacent “normal” ground level)

2) drill through room above and take flue further vertical so it doesn’t exit the property horizontally until 300mm above normal ground level

3) anything else?

once again appreciate any advice you can give

Thanks